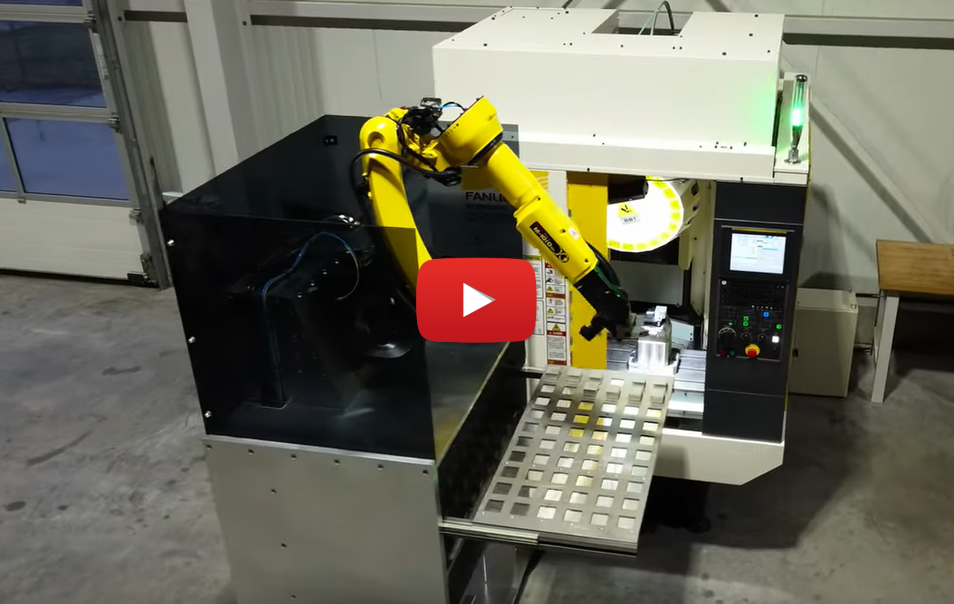

BASE-ROC

die Features:

With our new robot cell, you benefit from maximum productivity and minimal space requirements. Thanks to intuitive, dialog-style data input directly on the original handheld control unit, no robot programming knowledge is required. Even small production runs can be automated quickly and easily.

This robot cell is the first loading cell made entirely of aluminum. This makes it lightweight, robust, and extremely precise. Thanks to its bolted construction, it avoids the distortion often found in welded structures. And all this on a footprint of just 1 square meter!

Another highlight: The built-in laser scanner eliminates the need for fencing, making the cell very easily accessible.

The robot cell is versatile and can be mounted on both machining centers and lathes. Workpieces weighing up to 8 kg can be loaded and unloaded. Data exchange takes place via a hardware interface using M-functions. With a Fanuc Robodrill, communication is seamless via the integrated network interface.

Despite all our innovations, we offer this robotic cell at a very attractive price.

This also includes training your employees and commissioning at your premises.

Upon request, we can also handle the creation of a complete CE marking at a very attractive price.

This compact and powerful solution will take your automation to a new level!

Technical specifications:

Maximum workpiece weight: 8 kg

Gripper type: 1-way (standard)

Number of drawers with workpiece pallets: 3

Dimensions of the workpiece pallets: 1,100 x 550 mm

Max. loading weight per drawer: 100 kg

Footprint: 1200 x 800 mm

Cell height: 2,200 mm

Cell weight: approx. 680 kg

Power consumption: 1 kVA / 400 volts

Download Flyer

Gripper type: 1-way (standard)

Number of drawers with workpiece pallets: 3

Dimensions of the workpiece pallets: 1,100 x 550 mm

Max. loading weight per drawer: 100 kg

Footprint: 1200 x 800 mm

Cell height: 2,200 mm

Cell weight: approx. 680 kg

Power consumption: 1 kVA / 400 volts

Our Base-Roc in action: